Aqua Cast eco resin is an environmentally friendly fusion of powder and polymer which only needs the addition of water to make beautiful homeware.

Eli-Chem Resins has fused the acrylic polymer additives into one ground breaking powder to make this easy to use eco resin. All mechanical properties normally found in a traditional powder and polymer mixture remain the same, giving Aqua Cast excellent cured strength.

It couldn't be easier, simply add water, mix and pour.

The guide mix ratio is 100 : 35 (100parts powder to 35 parts water, or 2.8 : 1)

The user can change the water addition to create a lower or higher viscosity (runnier or thicker) to suit the individual application.

Easily coloured with water based pigments such as our resi-TINT acrylic inks, acrylic paints or mica powders, e.g. resi-TINT MAX Neon Powder.

- Environmentally friendly eco resin

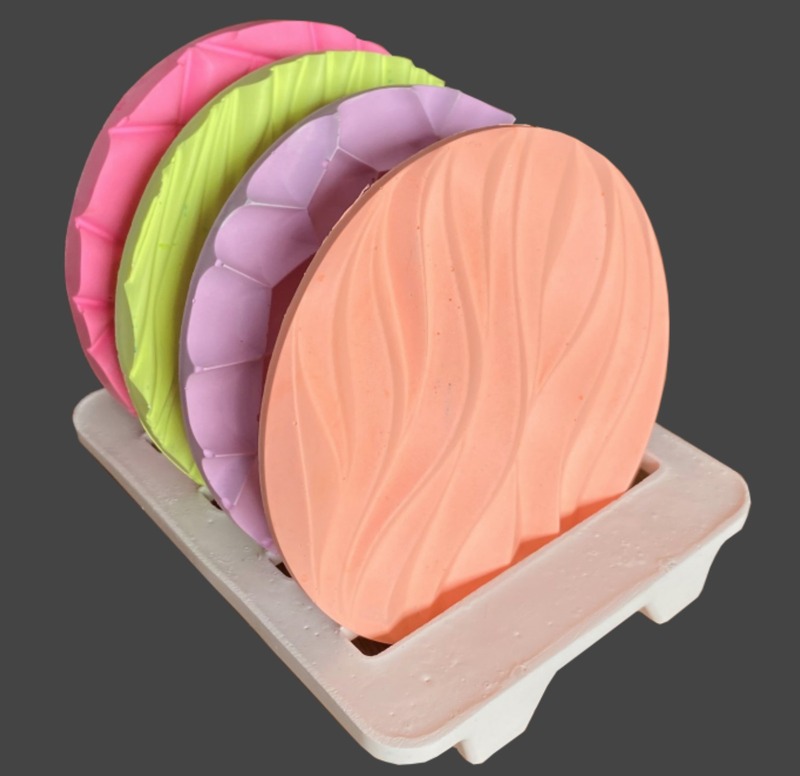

- Perfect for coasters, ornamental vases, planters, candle holders, soap dishes and detailed figurines

- Easily pigmented using resi-TINT inks or other water based pigments

- Ideal for ceramics & textured art pieces and can be partnered with our art resins when using a mould

- Excellent reproduction of detail

- Can be used to create terrazzo pieces

- High surface hardness and strength

- Smooth, impact resistant surface

- Fire protection class 1 (surface spread of flame)

- High degree of weather resistance for external applications when sealed

FAQ's

- Is Aqua Cast weatherproof and waterproof? No, it is porous when cured. For external applications and those where the article will hold water it will need to be sealed. We recommend our range of hydroflow Sealers

- How hard and durable is Aqua Cast? It is extremely tough and durable. Once cured Aqua Cast cures to a hardness of 208 MPa (Brinell) The compressive strength is 55 Mpa when mixed in the guide ratio of 100:35.

- Will it fade with exposure to sunlight? No this product is 100% UV stable.

- Is it fire-resistant? Yes, Aqua Cast does not self-ignite nor propagate flame. It is suitable for creating candle holders and fireplaces.

- Can Aqua Cast be used with art resin? Yes it can, an interesting mix of finishes can be achieved in one piece of art using Eli-Chem totalCAST art resin and Aqua Cast Eco Resin. Simply decide which medium to pour first and follow the guidelines for a second pour shown below. Both products are very easily coloured, the totalCAST can even have a clear or translucent finish. The limit to your creation is your imagination!

Specifications

- Drying time: Demould in 60-90 minutes, for maximum cured strength 24-48 hours

- Mix ratio: 100 : 35 (2.8 : 1) e.g. 100g of powder to 35g of water

- Pot Life: 10-15 minutes @ 23 degrees C

- Shelf life: Indefinite when kept dry in storage

Mixing

Adding colour: Use any water based pigment e.g. resi-TINT acrylic inks, acrylic paints or mica powders, e.g. resi-TINT MAX Neon Powder.

Any solid can be added, sand, mica, quartzite, dried shards of Aqua Cast etc.

Mixing the powder: The desired viscosity & consistency can be controlled to suit the application. Alterations to the guide powder to water ratio will affect the product performance, particularly in terms of drying time. Measure the desired amount of water, add the corresponding quantity of powder gradually during mixing. For example:

- 100g powder to 35g/ml water

- 150g powder to 52g/ml water

- 200g powder to 70g/ml water

- 300g powder to 105g/ml water

- 500g powder to 175g/ml water

Mix by hand or with an electric mixing blade for 2-4 minutes until uniform and smooth. Add pigments at the mixing stage to obtain the desired colour shade. The mixed solution will rapidly become creamy and lump free, tap the mixing container to help remove trapped air.

Application

Immediately pour into your mould and allow to settle. Any residual bubbles can be popped by agitating or tapping the mould. Allow to harden for 60-90 minutes before demoulding (temperature and mix ratio dependent). Allow to dry for 24-48 hours to build cured strength.

When pouring Aqua Cast onto previously poured resin, please ensure the resin has entered the gel phase but is not yet touch dry to allow the Aqua Cast to adhere. This will vary depending upon depth and size of the mould. If you think you have missed the gel window, wait for the resin to dry, and thoroughly abrade to create a key before pouring Aqua Cast.